3D Scanning FAQs

The answer is; it depends. If your object is smaller than a baseball, we have straight forward No Haggle Pricing. If the object is larger, then it depends on the three factors; size, shape & complexity. To calculate a cost, you may use our Scanning Cost Calculator and we will be happy to provide you with a quote for the job.

The scanner we use is able to capture down to the micron level, down to 10 µm. This does not automatically mean something that tiny can be scanned. It just means that under optimal conditions, something less than 1mm square can be captured. To achieve such results, the object must “scannable”. To be so, the item must be light in color with a matte / flat surface. In general, objects down the size of hard drive mounting screw can be relatively easily scanned. The level of detail will depend on the surface quality and whether or not a non-reflective coating has to be applied. Please see the surface prep FAQ for more information.

In general, there is no limit. In reality, there are hardware and software limitations. The larger the object, the greater the resources which are required. Even with multi-terabyte hard drives, file sizes can become too large for even the most capable PC’s to handle.

This being said, one of the ways we work around such limitations is to scan large objects, such as a car or truck, in smaller sections and process them individually before stitching the fusions together. In this way, we can easily scan a vehicle, statue, memorial and most anything up to the size of a pickup truck.

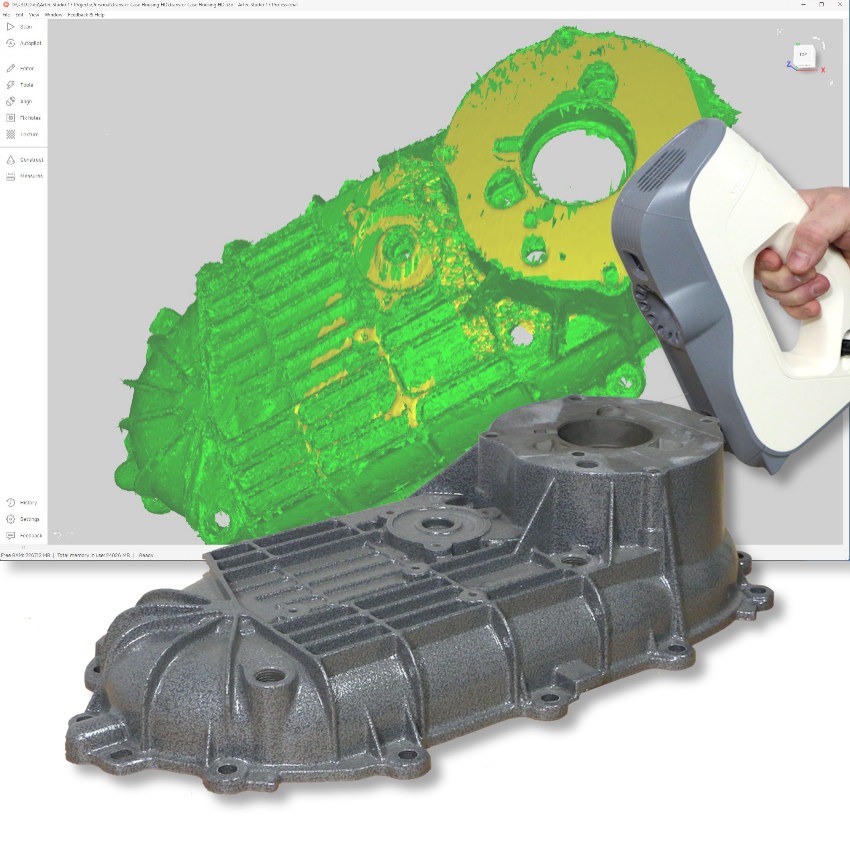

Surface quality plays a critical role in 3D scanning as it impacts the accuracy and detail of the 3D model created. When surfaces are smooth and uniform, it produces a clean and accurate scan. Conversely, when surfaces have unevenness, scratches, or rough edges, it can cause issues during the scanning process. Many scanability issues can be remedied prior to scanning by using a self evaporating scanning spray to reduce reflectivity and make small details stand out.

Poor surface quality may cause light to reflect irregularly, resulting in incomplete or inaccurate scan data. The rough surface may also prevent the scanner from making contact with the object, leading to incomplete data sets.

The texture also influences the kind of scanner that needs to be used. Generally, a structured light scanner frequently used for capturing details of a surface, is suitable for glossy surfaces offering high-resolution results. On the other hand, a laser scanning device provides greater accuracy and resolution for textured surfaces. In summary, having a high-quality surface is crucial in producing the most accurate and detailed 3D models.

When the surface of the object to be scanned is highly reflective, such as chrome or a surface with a high gloss finish, we use a specialty scanning spray specifically for this challenge. It’s made in Germany by Aesub. It is a self vanishing coating that will not harm, or otherwise affect the surface on which it is applied. (see more)

Once the scanning is complete and the 3D model has been created, the model is brought into a special application that assists our staff identify and convert shapes into fully defined CAD objects. After the assisted conversion, our engineers take over to finish the conversion for reverse engineering. The result is a fully featured object tree which can be exported in various CAD formats.

Geometric complexity refers to how intricate an object’s shape is, including the number of surfaces, curves, and edges that it has. When using 3D scanners to capture the shape of an object, geometric complexity can affect the accuracy and efficiency of the scanning process. Not all objects are suitable for scanning.

Firstly, more complex objects usually require more time and effort to accurately capture their entire shape. This is due to the fact that 3D scanners typically take multiple images or scans from different viewpoints, and geometrically complex objects can be harder for the scanner to capture in their entirety.

Secondly, 3D scanners may also struggle with identifying and capturing the intricacies of a highly complex object. Software algorithms used in 3D scanning may have trouble rendering and stitching together the images and data points collected from complex objects, leading to inaccuracies and errors in the resulting scan.

Overall, the geometric complexity of an object can significantly impact the effectiveness and accuracy of the scan. To find out if it’s a good candidate to be scanned into a 3D model, contact us and we’ll be happy to discuss your situation.

We can scan people. We will only scan adults. Children are naturally energetic and it’s challenging for them to sit perfectly still for the time necessary to complete a scan.

We do not scan live animals.

Precision, Quality, Delivered Worldwide

Email us:

info@3dscanstl.com

Contact

314-730-0150

info@3dscanstl.com

Our Address

10758 Trenton Ave Saint Louis, MO 63132