3D Scanning Reverse Engineering Services:

What it is & What it Costs

Professional 3D scanning services are available across the country. However, expert 3D scanning can be challenging to find. In Saint Louis and the Midwest region as a whole, 3D Scan STL is the leader in scanning and reverse engineering. The combination of advanced laser and structured light scanning technology with local accessibility ensures you get both technical excellence and convenient service delivery. Whether you need support for reverse engineering, assistance with rapid prototyping, or detailed quality inspections, professional scanning providers offer the precision and reliability your projects require.

How it works

At 3D Scan STL, we understand the importance of transparent and upfront pricing when it comes to 3d scanning reverse engineering services. That’s why we have designed our pricing structure to be simple and straightforward. We believe that our customers deserve to know exactly what they are paying for, without any hidden fees or surprises.

Whether you need a small object scanned for personal or professional purposes, our team of skilled experts is here to help. From start to finish in the 3D reverse engineering process, we will keep you informed, ensuring that you receive exceptional service and accurate results. Our state-of-the-art technology allows us to capture every detail of your objects with precision and clarity. When it comes to 3D modeling, product visualization, or any other application, you can count on us to deliver excellent results.

Understanding the Process of

3D Scan to CAD Conversion

The process of converting a physical object into a digital CAD model involves several steps. It combines 3D scanning technology with advanced processing techniques.

The process of converting a physical object into a digital CAD model involves several steps. It combines 3D scanning technology with advanced processing techniques.

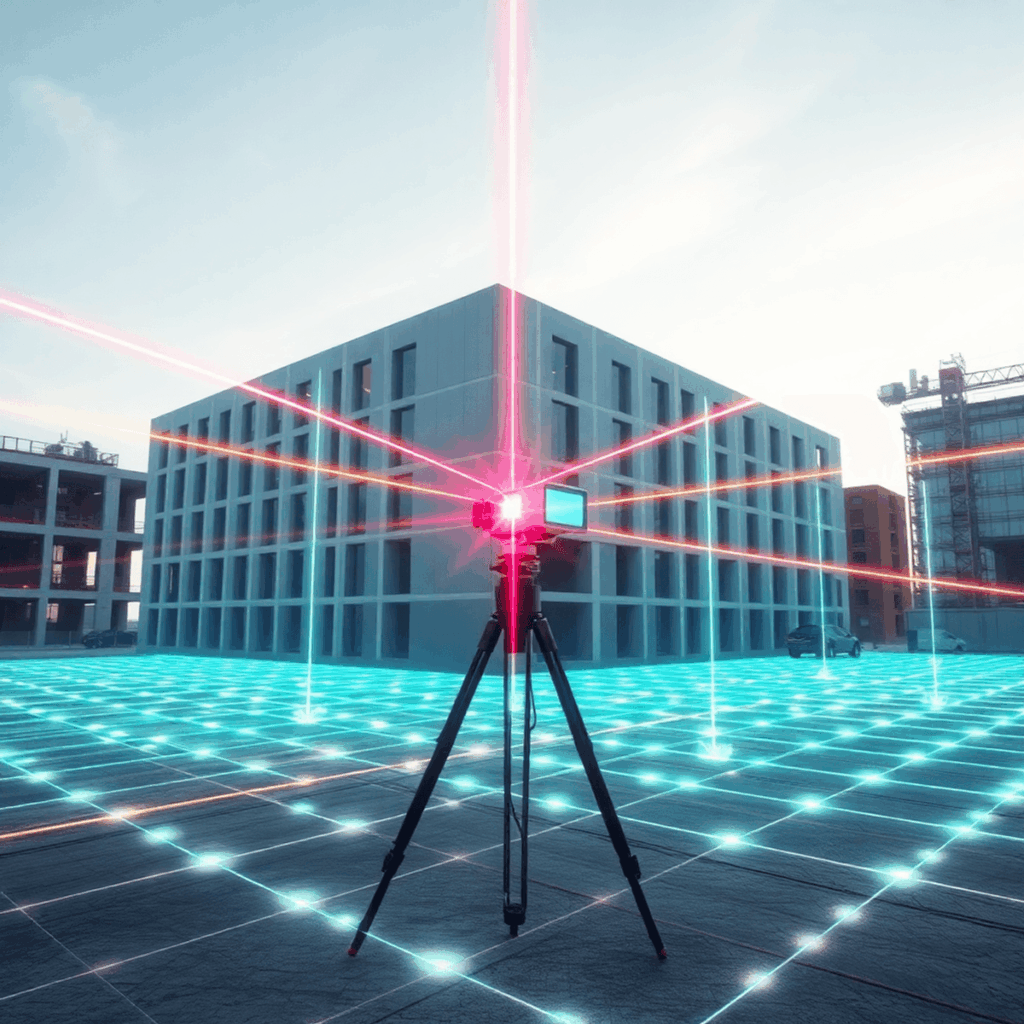

Step 1: Data Acquisition

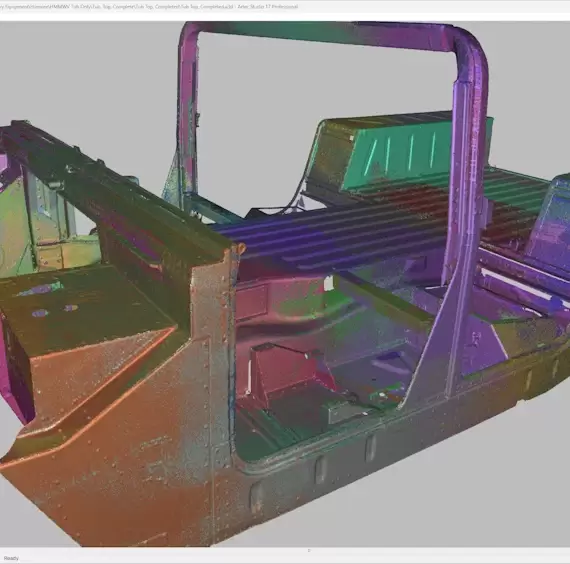

The first step is data acquisition. In this phase, specialized scanners are used to capture millions of coordinate points that represent the object’s surface geometry. This generates raw data in the form of point clouds or mesh files, creating a digital representation of your physical part.

There are different methods for capturing digital geometry based on your specific needs and the characteristics of the object. We have five elite professional scanners we use. This means we have the right tool for the job.

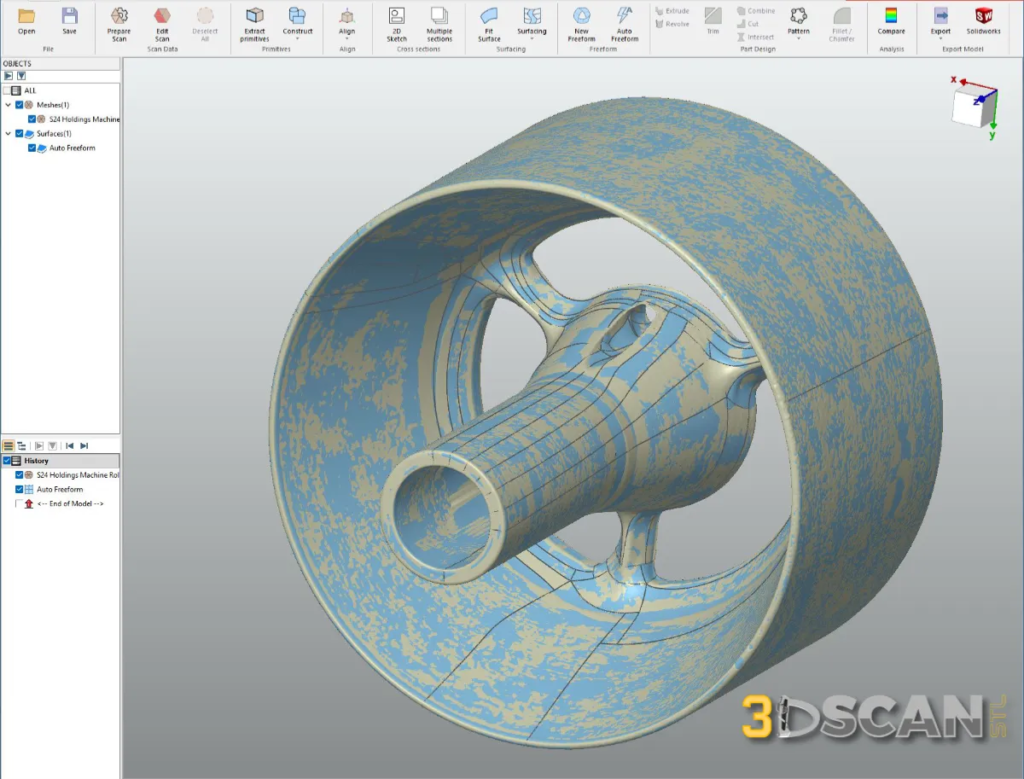

Step 2: Processing with Reverse Engineering Software

Once the scan data is processed, it’s time to use reverse engineering software. These specialized tools are designed to interpret the raw point cloud or mesh data.

In this step, the software performs several tasks:

- Filtering noise: It removes any unwanted or irrelevant data points from the scan.

- Organizing information: The software breaks down the scan data into manageable segments.

- Analyzing geometric patterns: It looks for specific shapes and features within the scan, such as cylinders, planes, and freeform surfaces.

Two variants of our 3D scan to CAD conversion service

3D Scan to CAD Conversion Service with Surface Modeling (Surface Reconstruction)

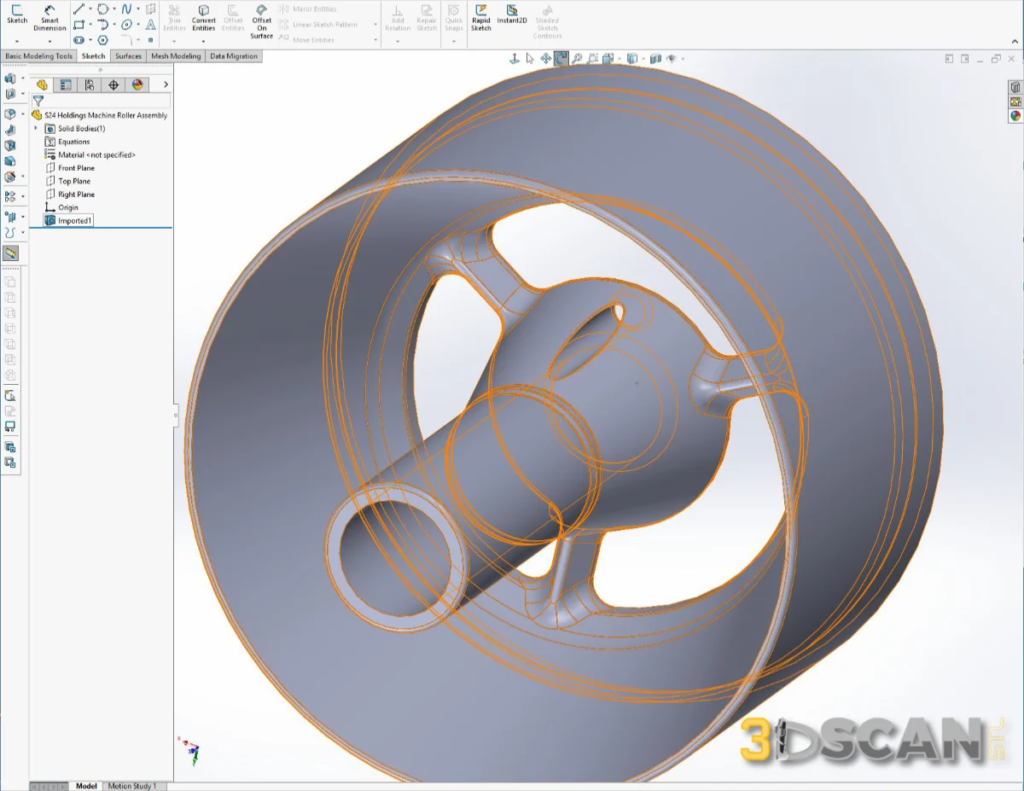

3D Scan to CAD Conversion Service with Parametric Modeling (Parametric Reconstruction)

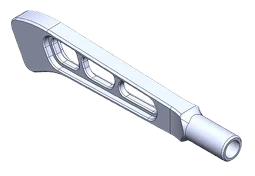

We provide a service to convert a 3D scan (STL) into a CAD model (STEP) using surface modeling. This process involves using NURBS surfaces to shape the 3D scan and create a CAD model. The resulting CAD model is made up of NURBS surfaces, which are perfect for measurements in CAD or as a reference model. However, please note that it is not suitable for further modeling as the NURBS surfaces are nearly impossible to edit.

We provide a service that converts a 3D scan (STL) into a CAD model (STEP) using parametric modeling. This process, known as precise Parametric Reconstruction, involves optimizing the 3D scan during the conversion to CAD. Any areas that are not captured in the 3D scan are logically filled in, and any inaccuracies are corrected and adjusted to meet industry standards. Additionally, upon request, we can also include feature history and technical drawings with the CAD data.

Cost

There is no ‘set’ cost for either of these services. However, we strive to make the process as transparent and cost effective as possible. There are a tremendous number of variables that go into the pricing formula to come up with a number.

- How large is the data file?

- How complex is the geometry?

- In which format will the conversion be completed?

- Something often overlooked – how quickly does it need to be delivered?

All of these factors affect the project cost. We work with you to find a solution that meets your needs, without pressure, without any upselling and without drama.

Contact us for a free quote today. Your project is too important to entrust to just anyone.

Applications

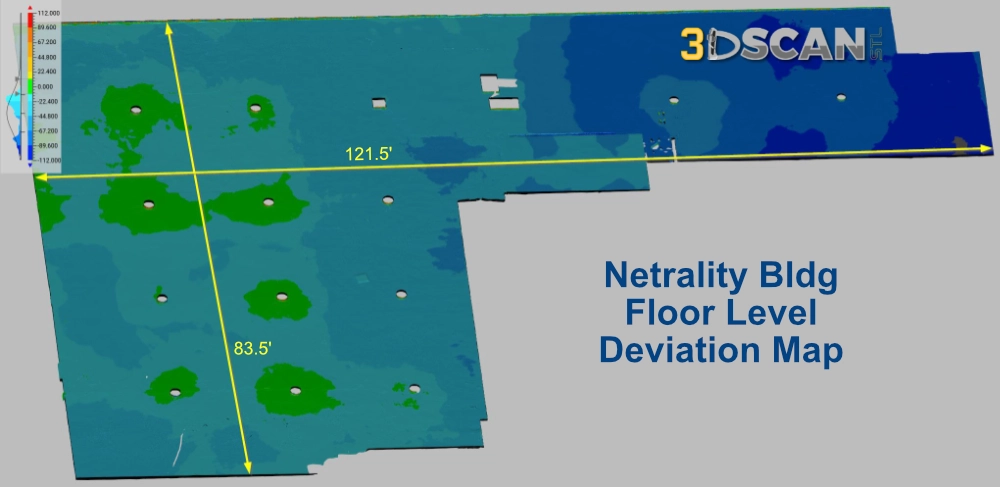

Non-Contact Measurement

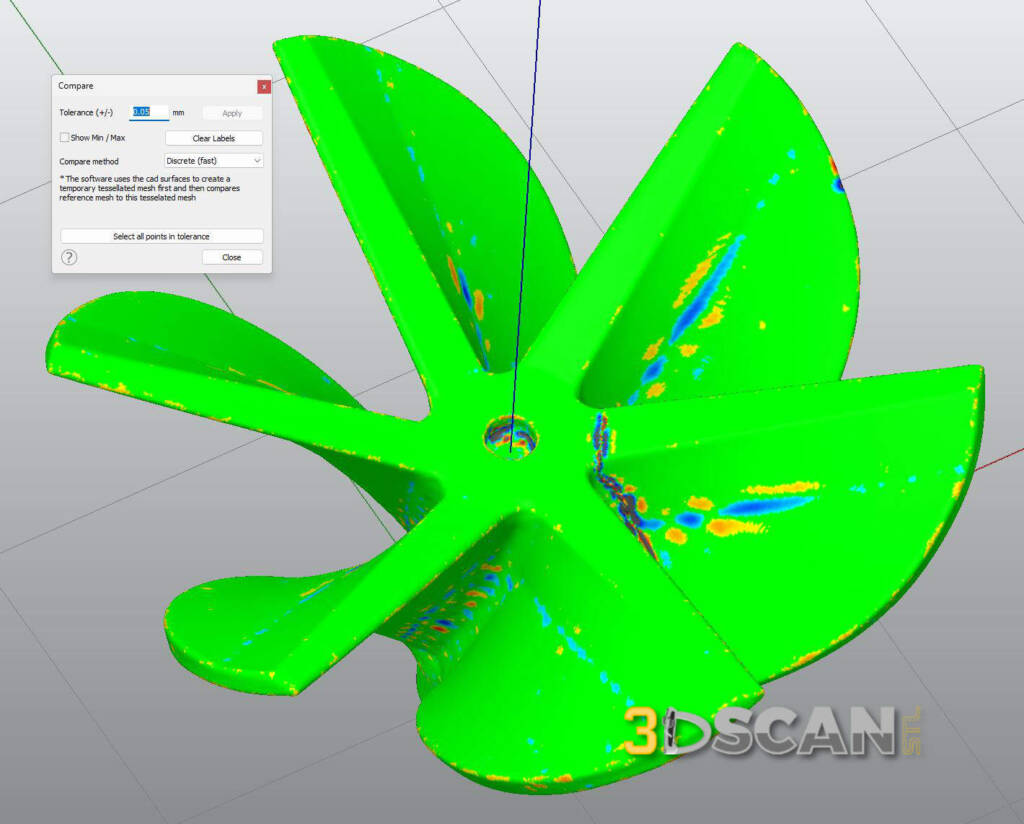

Inspection and Quality Control

Reverse Engineering

Product

Design

Trusted 3D Solutions

Precision, Quality, Delivered Worldwide

At 3D Scan STL, we specialize in high-accuracy 3D scanning, reverse engineering, and CAD modeling. Using the latest scanning technologies, every project is handled with care and shipped or delivered digitally worldwide. Reach out today—just fill out the contact form, and let us help bring your designs to life.

- 314-730-0150

- List Item #2

- 10758 Trenton Ave Saint Louis, MO 63132

Contact us

Blog