Automated Industrial Production Line

An industrial parts manufacturer came to us with a problem they wanted solved. They were working on expanding one of the assembly stations and had all of the plans already created in CAD. However, they had no accurate means of determining spacial distances between key components of their existing production station and without these measurements, could not be fully confident in commencing work on the new system. This is where we came in. We were able to scan the full production area of which they required these measurements and create an accurate 3D spacial model for them to utilize as a means to validate their new designs.

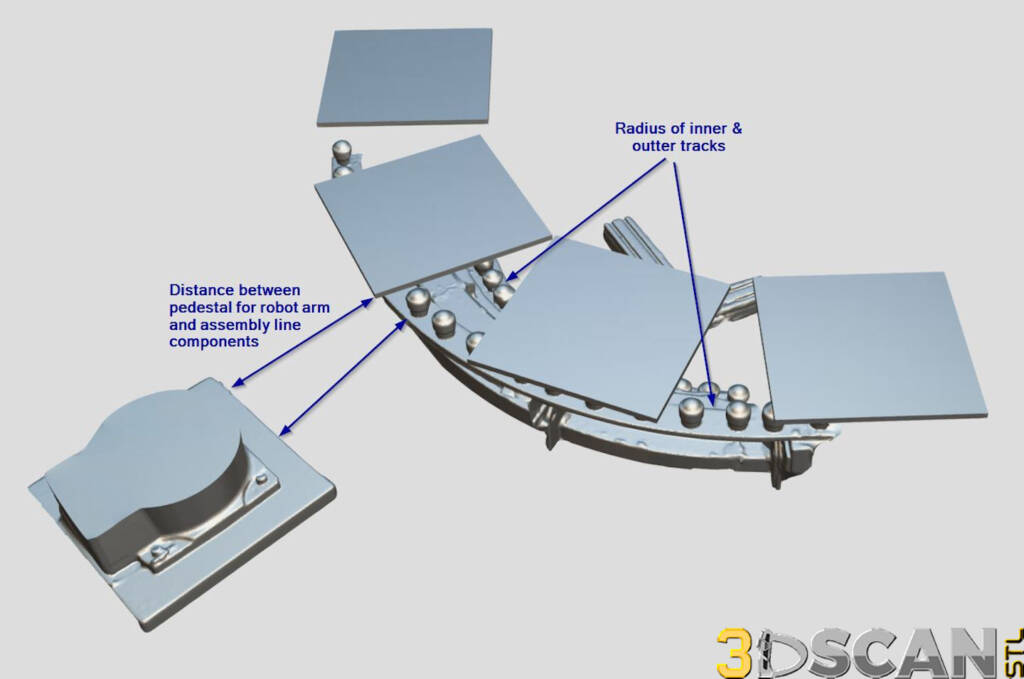

Specifically, they needed to know a few specific measurements. The radius of the inner and outer support tracks upon which the production plates roll over as they travel in a closed circuit. They also needed to know the exact distance, both laterally and vertically, of the robot arm’s base from the the production plates and the guide supports. The only effective and efficient means of doing so is through the magic of 3D scanning. We were able to accurately capture all of this information and deliver a complete 3D model for their project. What’s more, we did so in less than 48 hours. This included traveling to their facility near Union, Missouri to scan their equipment.

No job is too small, or too large, for us to handle. Whatever your need, 3D Scan STL will meet it.