Elevator Motor Unit, Large

We were contracted again by Hollister-Whitney to scan a couple of elevator motor units at their facility in Quincy, Illinois. These were very large and very heavy assemblies. It took about an hour each to scan them both and a little bit more time to capture the brackets as well. This unit weighs over 2500lbs and posed some challenges with scanning. The objective was to capture the major dimensional data for use when designing the framework for mounting of this monster.

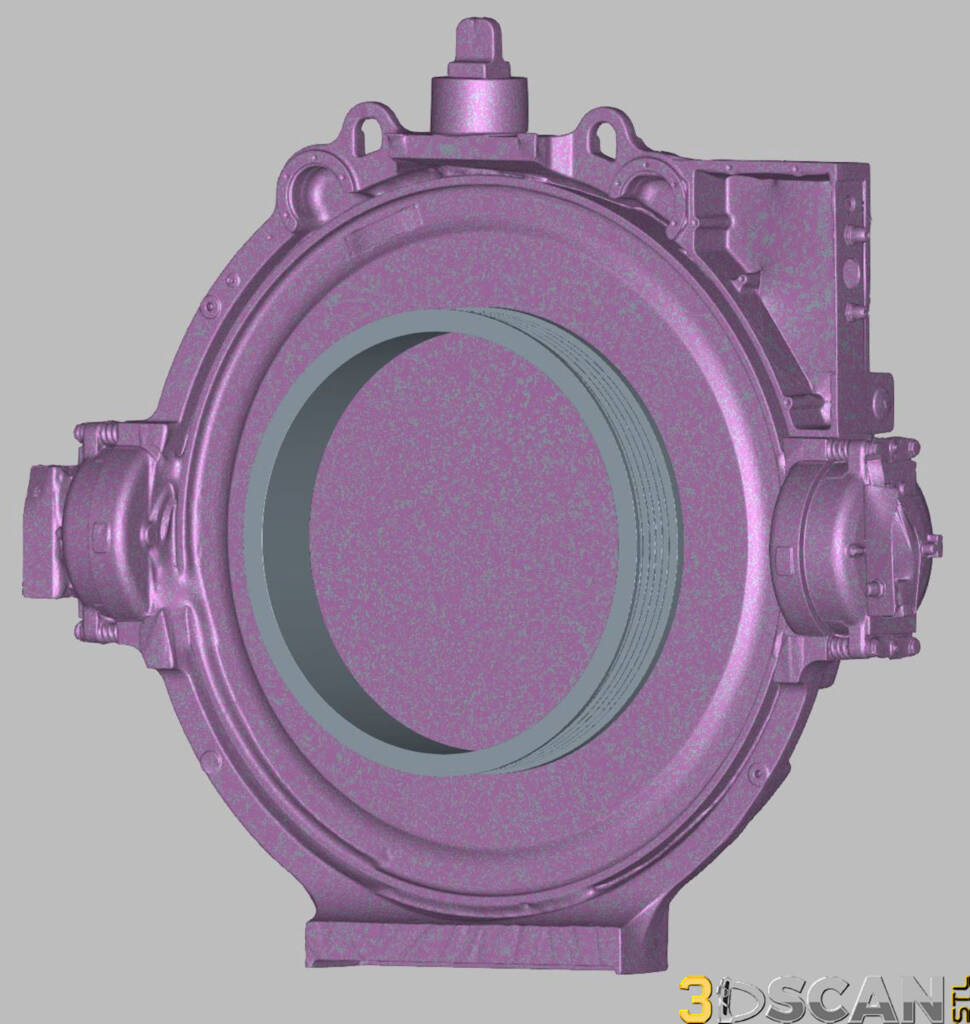

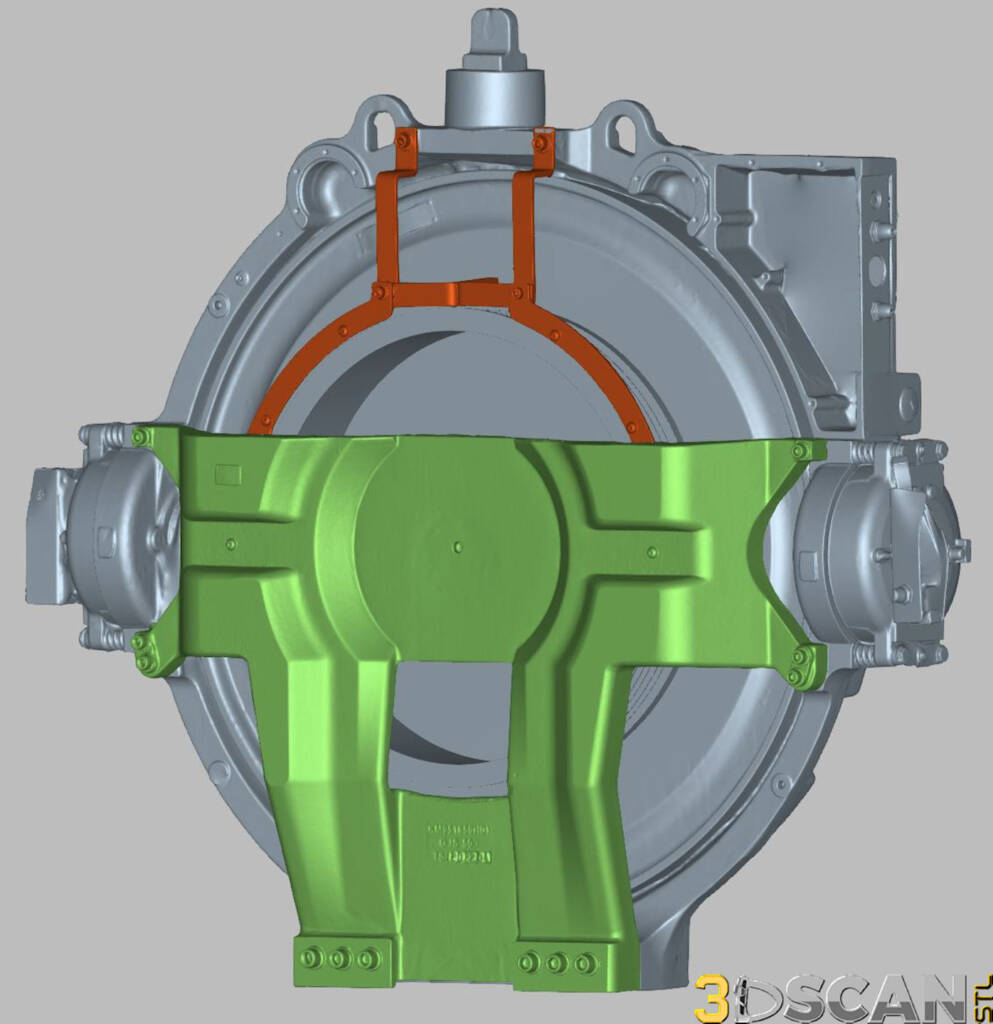

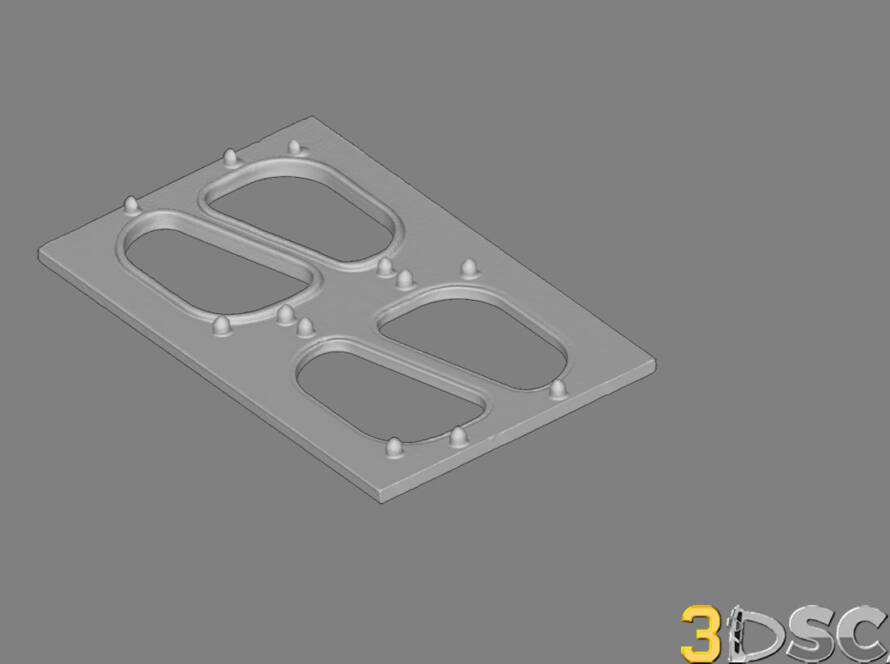

After scanning, the goal was to create a solid object for use in CAD. However, due to the file size of the model which was generated, the conversion resulted in a file over half a gigabyte. To keep the data manageable, we digitally disassembled the motor unit so the smaller pieces would consume fewer hardware resources for processing the step files. We also utilized our advanced conversion applications to convert some objects directly into CAD ‘privatives’ with the exact same dimensions, including the cable drum which was impossible to scan fully due to be its being mostly obscured from view.

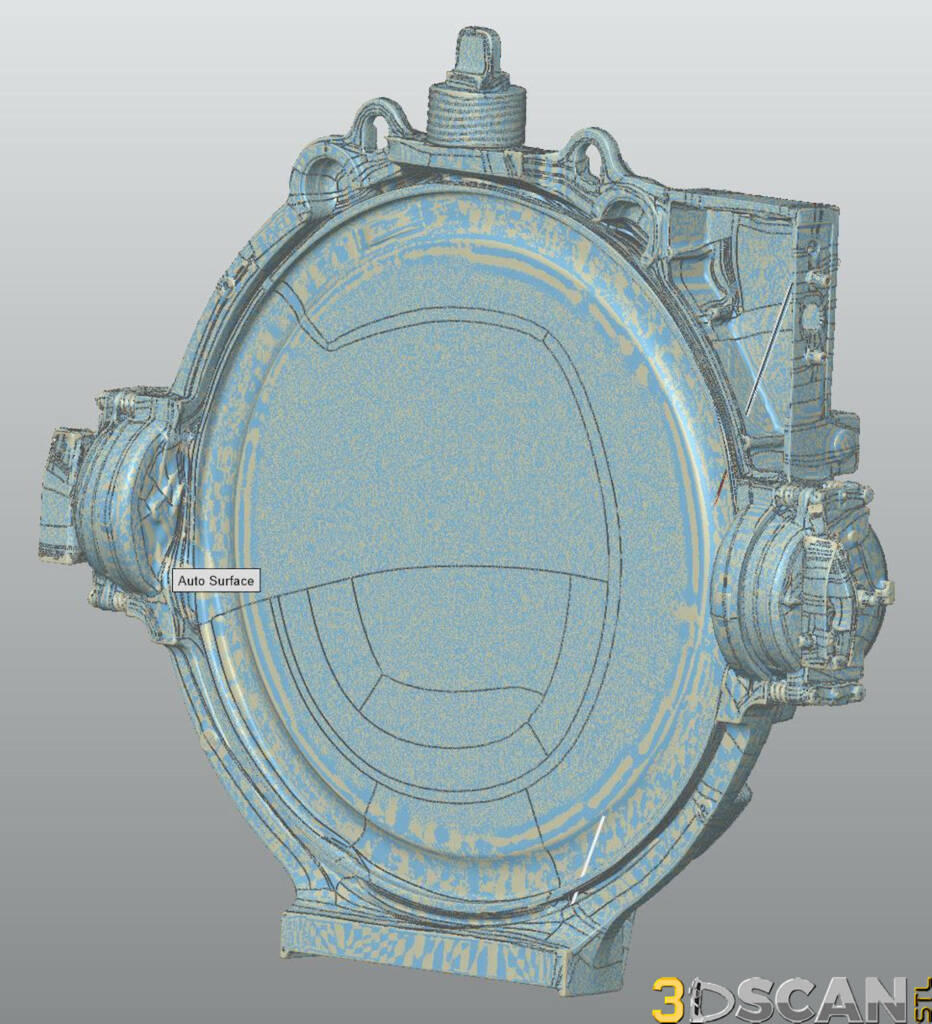

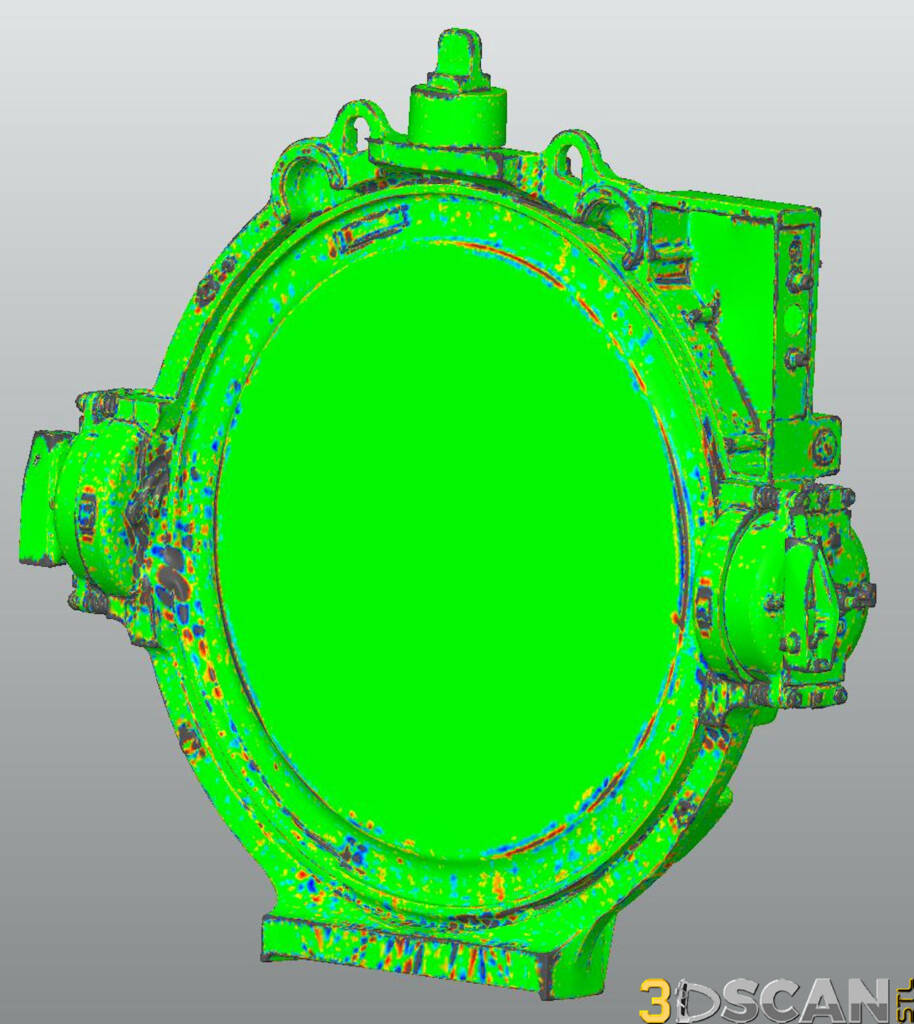

Below are the results of the conversion to a solid CAD object. On the left is the surface wrap converting the mesh into a solid object. On the right is the deviation analysis showing the tiny areas in which the surface wrap does not ‘touch’ the mesh surface perfectly. As you can see, the tiny areas of deviation are incredibly minor and do not pose any challenges for the engineers who use this for their design work.

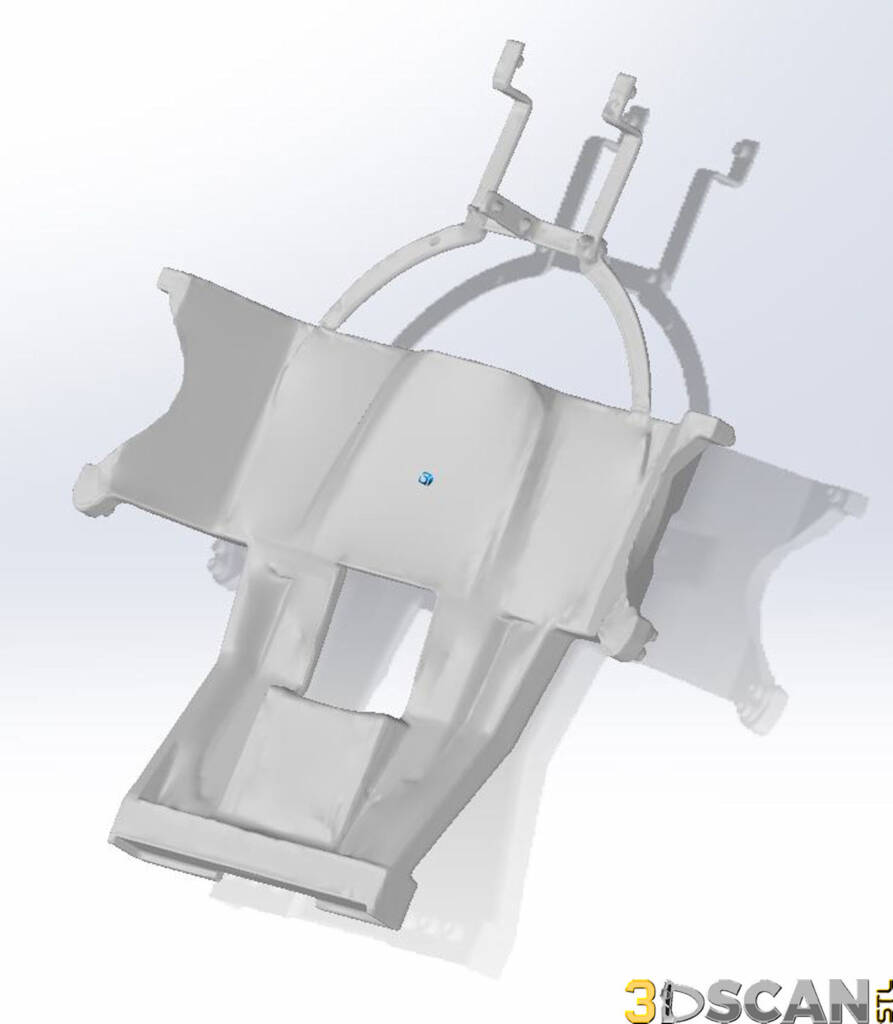

Below, the front section has been converted to CAD and is displayed in SolidWorks.