Professional 3D Scanning makes all the difference

Professional 3D scanning services are available across the country. However, expert 3D scanning can be challenging to find. In Saint Louis and the Midwest region as a whole, 3D Scan STL is the leader in scanning and reverse engineering. The combination of advanced laser and structured light scanning technology with local accessibility ensures you get both technical excellence and convenient service delivery. Whether you need support for reverse engineering, assistance with rapid prototyping, or detailed quality inspections, professional scanning providers offer the precision and reliability your projects require.

What exactly is 3D Scanning?

D scanning, also known as 3D digitization or 3D imaging, is a technology that involves capturing the physical shape, structure, and appearance of real-world objects to create digital 3D models. This is a process where the geometry and often the texture or color of an object are recorded to generate a three-dimensional representation of the object in a digital format.

3D Scanning Process Explained

Data Capture

- Sensors and Devices:

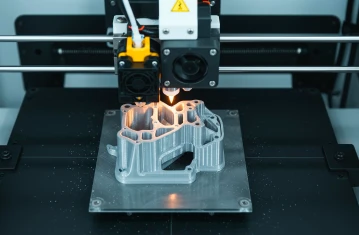

Specialized scanners with lasers, structured light, or other technologies, are used to capture data from the surface of an object.

- Data Acquisition: The scanner emits light towards the object, and the reflected or emitted light is detected by the scanner’s sensors. These sensors record the distance, shape, and texture of the object’s surface.

Point Cloud Generation

- Point Cloud: The data is captured as a point cloud, which is a large collection of x, y, z coordinates in 3D space. This represents the surface of the object.

Mesh Creation

- Meshing: Using specialized software, the point cloud is processed to create a mesh. The mesh is a digital representation of the object’s surface. A mesh is made up of interconnected vertices, edges, and faces that define the geometry of the object.

Texture Mapping

- Texture Capture:

In addition to geometry, some 3D scanners also capture color or texture data during the scanning process.

- Texture Mapping: The captured texture data is mapped onto the 3D mesh. This creates a realistic representation of the object’s surface, including its color and appearance

Some of the uses for 3D Scanning

The resulting 3D model can be used for a wide range of applications, including but not limited to:

- Manufacturing: Prototyping, reverse engineering, and quality control.

- Entertainment and Gaming: Character design, animation, and virtual environments.

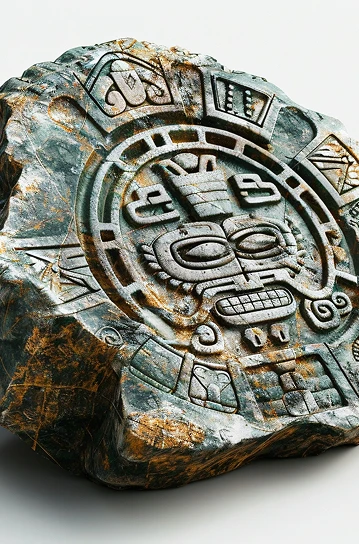

- Archaeology and Cultural Heritage: Preservation and analysis of artifacts and historical sites.

- Medical and Healthcare: Custom prosthetics, orthotics, surgical planning, and visualization.

- Design and Architecture: Architectural modeling, interior design, and urban planning.

- Education: Learning and interactive educational content.

Overall, 3D scanning is a powerful tool that creates a digital representation of physical objects. This enables a wide range of applications across various industries.

What can 3D scanning do?

3D scanning offers many capabilities and applications across various industries due to its ability to capture and digitize real-world objects in three dimensions. Here are some of the key things that 3D scanning can do:

In essence, 3D scanning transforms physical objects into digital data. A wide range of applications across diverse industries used this to improve efficiency, innovation, and understanding of the physical world.

3D scanning has many applications across various industries. This is due to its ability to capture and digitize real-world objects in three dimensions. Here are some of the key things that 3D scanning can d

Reverse Engineering

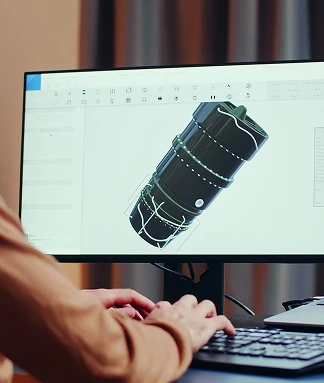

3D scanning can be used to reverse engineer existing physical objects. Thereby allowing for the creation of digital models that replicate their shape, structure, and features. This is particularly useful for redesigning or improving existing products.

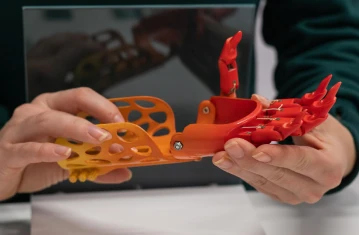

Prototyping and Product Development

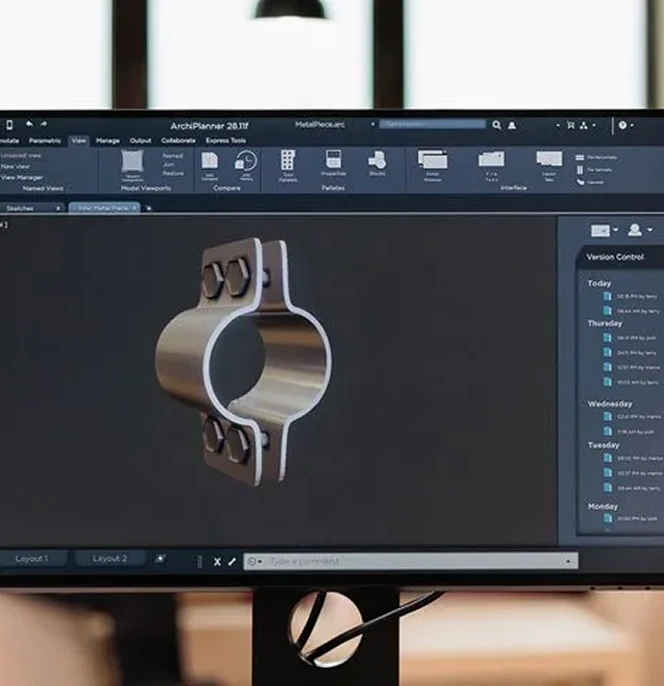

3D scanning is crucial in product development for creating prototypes and refining designs. It allows designers and engineers to rapidly capture real-world objects, saving time and resources in the product development cycle.

Quality Control and Inspection

Manufacturers use 3D scanning to inspect and analyze the manufactured parts or products to ensure they meet specific quality standards. Deviations from the intended design can be identified and corrected, maintaining high-quality production.

Customization and Personalization

3D scanning allows for the customization of products to suit individual preferences and requirements. This is particularly relevant in industries such as healthcare (custom prosthetics), fashion (tailored clothing), and consumer goods.

Archiving and Cultural Heritage Preservation

Virtual Reality and Simulation

Animation and Film Industry

Medical and Healthcare

What is the next step?

Funny you should ask. The answer is; first, it depends on what you intend to do with the 3D model once it’s created. This also dictates how the object will be scanned. Options such as capturing texture information are important when archiving and preserving an item such as a piece of art or a stunning piece of architecture. If your needs are strictly technical such as reverse engineering or quality inspection, high definition data is necessary to create a ‘solid object’. Next, once converted to a solid object, you can bring it into your preferred CAD software such as SolidWorks, Fusion 360, FreeCad, etc.. Another major use of 3D scanning is to capture and recreate obsolete parts for vehicles, homes, industry and/or manufacturing. In many cases, the 3D model is sufficient for parts duplication without the need to convert the item into a solid CAD object.

Understanding 3D Scanning

Professional 3D scanning transforms physical objects into precise digital replicas using cutting-edge measurement technology. You receive highly accurate three-dimensional models that capture every surface detail, texture, and geometric feature of your original item. These services go beyond basic photography or simple measurements—they create comprehensive digital twins suitable for engineering, manufacturing, and design applications.

Applications Across Industries

Industrial 3D scanning Services

Transforms how businesses approach design challenges and quality assurance across multiple sectors. You’ll find these services revolutionizing manufacturing processes from small precision components to massive industrial equipment.

Automotive 3D scanning Services

Leads the charge in vehicle development and maintenance. Car manufacturers rely on this technology to capture existing parts for redesign, analyze crash test results, and ensure perfect fitment of aftermarket components.

Reverse engineering applications

extend beyond traditional manufacturing. Mining operations scan conveyor systems and heavy machinery to maintain equipment efficiency.

Advantages of Choosing Local Providers

When searching for local 3D scanning services, you gain immediate access to providers who understand your regional market dynamics and industry requirements. 3D scanning near me searches connect you with professionals who can visit your facility within hours rather than days, eliminating shipping delays and potential damage risks during transport.

Reliable 3D scanning near me options offer face-to-face consultations where you can discuss project specifications directly with technicians. This personal interaction ensures your scanning requirements are clearly understood from the start, reducing revision cycles and miscommunication that often plague remote service relationships.

Local 3D Scanning Services deliver significant cost advantages through:

- Reduced shipping expenses for large or delicate components

- Lower travel costs for on-site scanning requirements

- Faster project completion with same-day or next-day service availability

- Real-time collaboration during scanning sessions

Regional providers also maintain specialized knowledge of local manufacturing standards and industry practices. You benefit from their established relationships with nearby fabrication shops, engineering firms, and quality control laboratories, creating a comprehensive support network for your scanning projects.

Selecting the Right Service Provider

Finding the best 3D scanning service provider requires careful evaluation of several critical factors that directly impact your project’s success. Experience stands as the primary indicator of reliability – you want providers who have handled projects similar to yours and understand the unique challenges your industry presents

Equipment Quality Matters

The quality of equipment used by the service provider plays a crucial role in determining the accuracy and resolution of your scans.

Ensure Project Scope Compatibility

It’s essential to ensure that the service provider you choose can handle your specific needs.

Pricing Transparency is Key

While it’s important to find affordable professional 3D scans, it shouldn’t come at the cost of quality.

FAQs (Frequently Asked Questions)

What are professional 3D scanning services and how do they work?

- Industries such as automotive (including cars and trucks), aerospace (aircraft), and various industrial sectors benefit greatly from 3D scanning. The technology is used for capturing everything from small devices to large-scale machinery like trains, aiding in design, quality control, and product development.

Benefits of industrial and automotive 3D scanning?

- Industries such as automotive (including cars and trucks), aerospace (aircraft), and various industrial sectors benefit greatly from 3D scanning. The technology is used for capturing everything from small devices to large-scale machinery like trains, aiding in design, quality control, and product development.

Why should I choose a local 3D scanning service provider near me?

- Industries such as automotive (including cars and trucks), aerospace (aircraft), and various industrial sectors benefit greatly from 3D scanning. The technology is used for capturing everything from small devices to large-scale machinery like trains, aiding in design, quality control, and product development.

What factors should I consider when selecting the best 3D scanning service provider?

- Industries such as automotive (including cars and trucks), aerospace (aircraft), and various industrial sectors benefit greatly from 3D scanning. The technology is used for capturing everything from small devices to large-scale machinery like trains, aiding in design, quality control, and product development.

Are professional 3D scanning services available nationwide with a focus on Saint Louis and the Midwest?

- Industries such as automotive (including cars and trucks), aerospace (aircraft), and various industrial sectors benefit greatly from 3D scanning. The technology is used for capturing everything from small devices to large-scale machinery like trains, aiding in design, quality control, and product development.

How does reverse engineering enhance professional 3D scanning services?

- Industries such as automotive (including cars and trucks), aerospace (aircraft), and various industrial sectors benefit greatly from 3D scanning. The technology is used for capturing everything from small devices to large-scale machinery like trains, aiding in design, quality control, and product development.