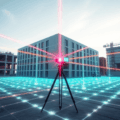

Tracking 3D Scanners for Large-Scale, Marker-Free Accuracy

At ScanTech 3DScan STL, our Tracking 3D Scanners offer industrial-grade precision without the need for markers. Utilizing advanced optical tracking and intelligent positioning, these scanners make it easy to capture large objects and complex geometries with speed and accuracy. Perfect for automotive, aerospace, and manufacturing applications, our tracking solutions simplify large-scale 3D measurement while improving workflow efficiency and quality control.

What Are Tracking 3D Scanners?

Tracking 3D scanners use real-time optical or infrared systems to monitor the scanner’s position and orientation. This allows for marker-free scanning of large components, eliminating manual alignment and reducing setup time.

At 3DScan STL, our tracking scanners combine dynamic referencing, hybrid tracking, and intelligent optics to deliver consistent, high-precision results. These systems are designed for industries that demand speed, scale, and accuracy, from automotive production to aerospace assembly and industrial research.

Our Tracking 3D Scanner Lineup

TrackScan Series

The TrackScan Series delivers high-speed, marker-free optical scanning for large objects. Its intelligent algorithms capture millions of points quickly, making it ideal for assembly lines, automotive parts, and industrial inspection. TrackScan ensures consistent results and integrates effortlessly with metrology workflows.

NimbleTrack Series

NimbleTrack is a wireless, portable 3D tracking solution designed for mobility and flexibility. Ideal for in-field scanning of prototypes, industrial equipment, or aerospace components, it combines convenience with professional-grade accuracy.

TrackProbe System

TrackProbe enables contact-based scanning for features that are difficult to reach with optical scanners. It is perfect for deep holes, hidden edges, or fine-detail inspection, completing a full industrial 3D metrology solution.

Trusted Across Industries

Our tracking 3D scanners serve professionals in multiple sectors that require precision and scalability:

- Aerospace & Automotive: Marker-free inspection of complex assemblies.

- Heavy Manufacturing: Efficiently scan large parts without alignment aids.

- Tooling & Mold Industry: Capture detailed surfaces in large molds and dies.

- Research & Development: High-speed scanning for experimental or custom projects.

- Energy & Engineering: Scan turbines, structures, and large assemblies reliably.

Want High-Precision 3D Data Instantly?

Why ScanTech 3DScan Tracking Scanners Stand Out

Marker-Free Precision

Eliminate manual target placement and save setup time with intelligent tracking algorithms.

Large-Scale & Complex Geometry Scanning

Capture expansive surfaces or intricate parts in a single session without compromising accuracy.

Real-Time, High-Speed Data Capture

Millions of points per second allow fast acquisition of large objects while maintaining industrial precision.

Dynamic Referencing for Stable Results

Compensates for vibrations or movement in the environment, ensuring accurate scans in challenging conditions.

Seamless Software Integration

Export directly to CAD, inspection, or reverse engineering platforms for immediate workflow application.

Advanced Technology for the Next Generation of 3D Metrology

Tracking scanners combine optical precision and intelligent automation to:

- Scan large surfaces quickly without reference markers

- Maintain accuracy over long distances

- Integrate data directly into CAD/CAM or inspection software

- Reduce manual alignment errors and rework

These advantages translate into faster turnaround, improved quality control, and lower operational costs.

Want the Full Details on Tracking 3D Scanners?

What Our Clients Have To Say

Frequently Asked Questions

A: A tracking 3D scanner uses optical or infrared systems to capture large objects or complex geometries without markers.

A: The system calculates position and orientation in real time, eliminating the need for manual alignment targets.

A: Yes, they are designed for large industrial parts, machinery, and complex geometries.

A: All 3DScan STL tracking scanners integrate seamlessly with CAD, reverse engineering, and inspection platforms.

Precision, Quality, Delivered Worldwide

Email us:

info@3dscanstl.com

Contact

314-730-0150

info@3dscanstl.com

Our Address

10758 Trenton Ave Saint Louis, MO 63132